Why Flooring Matters More Than You Think During Food Safety Audits

For food processing plants, commercial kitchens, and beverage facilities across Kentucky, passing a food safety audit is non-negotiable. It’s the critical validation that your operation meets the stringent standards set by regulatory bodies like the FDA and USDA. While most facility managers focus intensely on equipment sanitation, staff training, and process control, one of the most fundamental and often overlooked elements of compliance is your floor. KY Epoxy Flooring knows that your floor isn’t just a surface; it’s a foundational component of your food safety system.

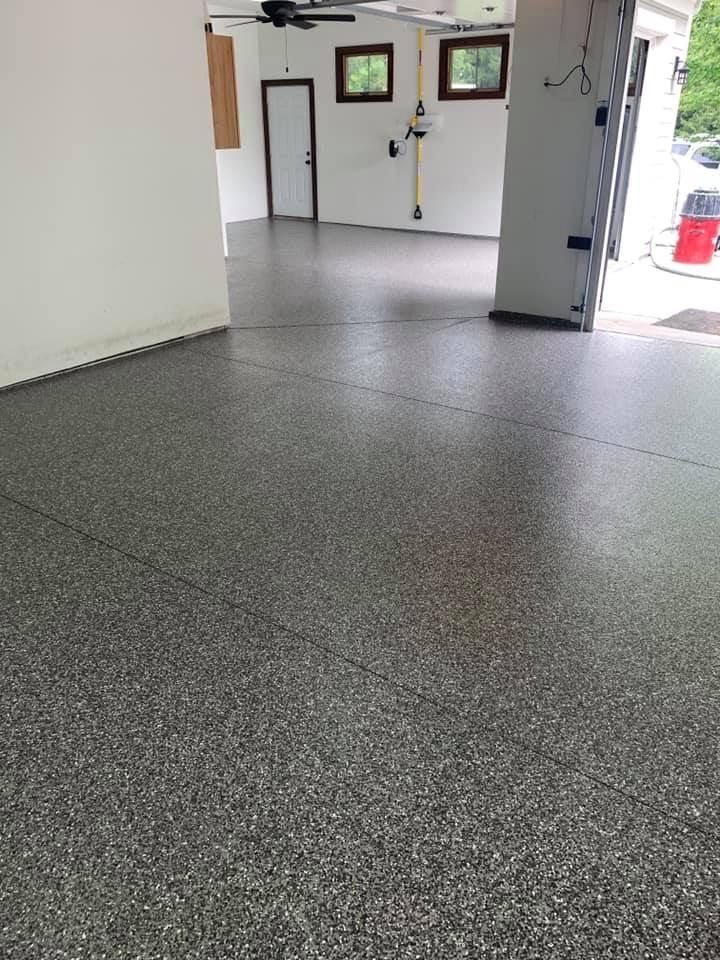

The flooring in a food facility is constantly exposed to moisture, harsh chemicals, temperature extremes, and heavy traffic. If your current floor is cracked, porous, or improperly installed, it can become a breeding ground for pathogens, leading to cross-contamination and immediate audit failure. This is why investing in high-performance KY epoxy flooring is one of the smartest decisions you can make for compliance and operational longevity.

The Hidden Risks of Subpar Flooring in Food Facilities

Auditors are trained to spot potential hazards, and compromised flooring is a major red flag. Traditional concrete, tile, or standard coatings simply cannot withstand the daily rigors of a food environment.

Porous Surfaces: Untreated concrete is highly porous, allowing moisture, oils, and organic matter to seep below the surface. This creates an ideal, protected environment for bacteria like Listeria and Salmonella to thrive, making complete sanitation difficult.

Cracks and Grout Lines: Tile floors and cracked concrete provide numerous seams and crevices where standing water and debris accumulate. These joints are notoriously difficult to clean and sanitize, offering pathogens a safe harbor from washdowns and chemical treatments.

Chemical Degradation: Food facilities rely on aggressive cleaning agents and sanitizers. Standard coatings can quickly degrade when exposed to these chemicals, leading to bubbling, peeling, and premature failure, which exposes the porous substrate beneath.

When an auditor sees these issues, they see a direct threat to public health and your operation's compliance status.

Essential Flooring Features for Audit Compliance

To meet the strict guidelines of a food safety audit, your flooring must be designed and installed to meet specific criteria. Our KY epoxy flooring systems are engineered to meet all of these requirements, helping you pass your next inspection with confidence.

| Feature | Audit Requirement | KY Epoxy Flooring Solution |

|---|---|---|

| Seamlessness | Must be joint-free to prevent microbial harborage | Our coatings are applied as a fluid, monolithic surface that eliminates all seams, cracks, and grout lines. |

| Imperviousness | Must be non-porous and water-tight | Epoxy and urethane systems create a dense, non-absorbent barrier that prevents liquid penetration. |

| Chemical Resistance | Must withstand aggressive cleaning agents and acidic/alkaline spills | We use specialized, high-solids formulations designed for superior chemical and thermal shock resistance. |

| Safety | Must provide a non-slip surface, even when wet | We incorporate anti-slip aggregates into the topcoat to create a safe, textured surface for employees. |

| Coved Base | Required where the floor meets the wall to facilitate cleaning. | We install integral coved base systems that seamlessly transition from the floor up the wall, eliminating the hard-to-clean 90-degree corner. |

The KY Epoxy Flooring Advantage: Our Commercial Concrete Coatings

KY Epoxy Flooring provides the high-performance solutions that food and beverage facilities demand. Our commercial concrete coatings are industrial-grade systems built for extreme conditions. We offer robust urethane cement and epoxy systems formulated to comply with FDA indirect food-contact guidelines and USDA requirements, making them the ideal choice for environments ranging from meat-processing and dairy plants to breweries and commercial kitchens.

We back our commitment to quality with a 10-year commercial warranty, giving you peace of mind that your investment is protected. Furthermore, our proven installation process is designed to minimize downtime. We understand that time is money, and our expert team works efficiently to prepare the substrate, apply the coating, and return your facility to full operation as quickly as possible. Typical projects can be completed in 2 to 5 days, depending on facility size and curing periods.

Helping Food Facilities Stay Compliant Across Kentucky

We’re proud to be the trusted provider of high-quality KY epoxy flooring solutions, serving businesses throughout the Bluegrass region, including Lexington, Louisville, Bowling Green, and all surrounding communities. When you partner with us, you aren’t just getting a new floor; you’re gaining a critical layer of protection for your business.

Don't let a failing floor compromise your next food safety audit. Take a proactive step toward compliance, enhanced safety, and long-term durability.

Contact us today to schedule a consultation and discover how our specialized epoxy systems can transform your facility into an audit-ready environment.